SINCE 1925

EGB FROM LEIPZIG

WHAT MAKES US SPECIAL?

ALMOST 100 YEARS OF EXPERIENCE

EVERYTHING FROM A SINGLE SOURCE

INNOVATIVE SPIRIT

100 YEARS OF HISTORY –

A JOURNEY THROUGH INVENTIONS, TECHNOLOGIES & INNOVATIONS

Our strengths lie in the development of high-quality and customised solutions, which we present to our contractual partners within a short period of time.

Projects are designed in 3D using CAD systems right from the design phase.

The company has been certified according to EN DIN ISO 9001 since 1996 and SCC since 2013.

Since 2023, Elektrotechnische Geräte Böhlitz-Ehrenberg GmbH has been shaping the energy revolution by electrifying previously diesel-powered construction machinery and projects in the field of renewable energies.

Elektrotechnische Geräte Böhlitz-Ehrenberg GmbH (EGB) was founded in Leipzig in 1925, making it a company with a real Leipzig tradition.

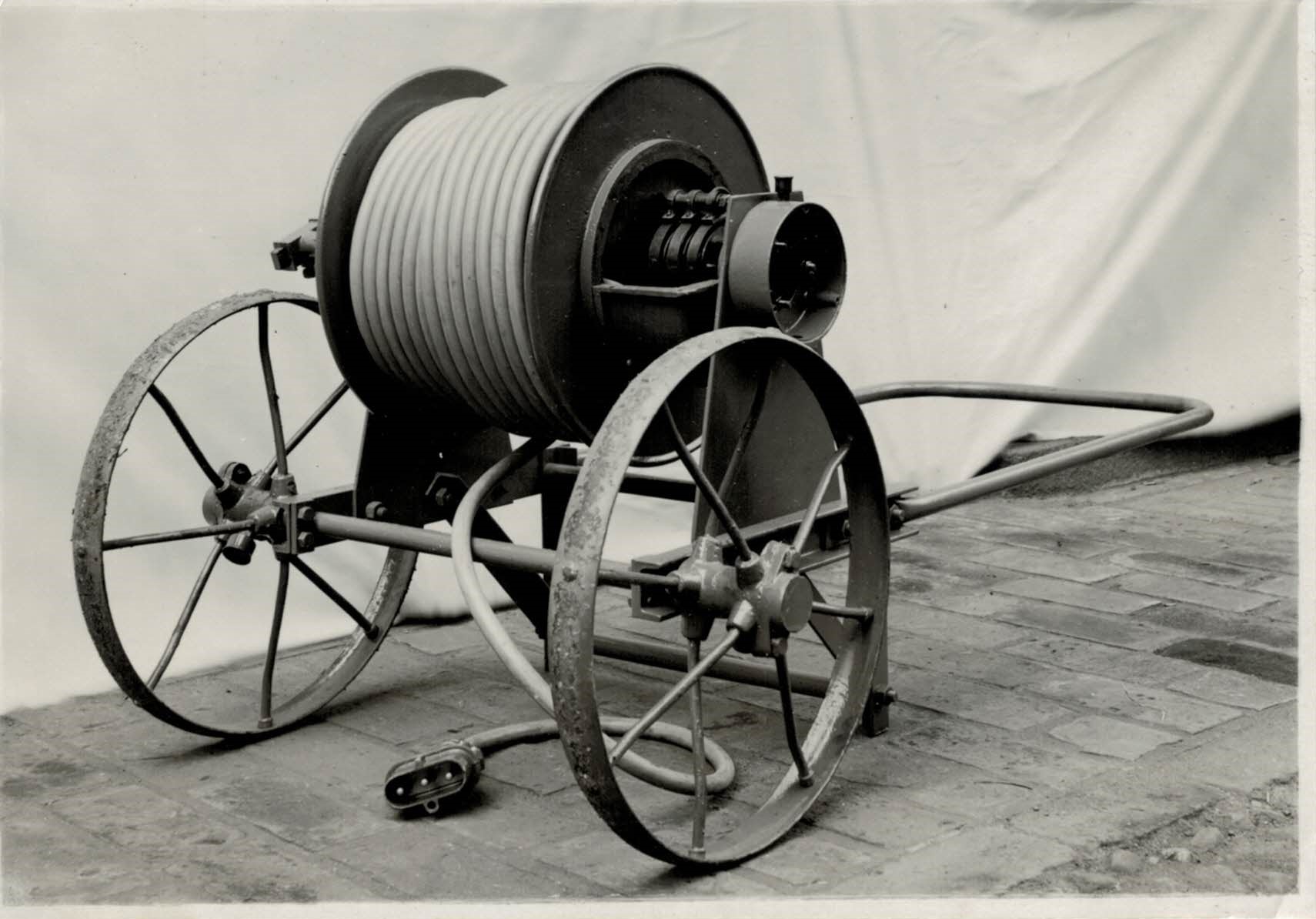

Initially, EGB manufactured a wide range of overhead contact line material for mine railways, crane runways and conveyor systems. It later expanded its product range with spring cable reels and motorised cable reels as well as lever limit switches. Its slip ring assemblies, which it continued to develop innovatively over the years, were a particular stand-out feature.

From 1953, the company continued to operate as “VEB Elektrotechnische Geräte Böhlitz-Ehrenberg”. The wide range of industrial switches, the versatile slip ring assemblies and the individually designed and built cable reels made a decisive contribution to the development of the hoist industry in the GDR in the post-war years.

The development of a mobile motorised reel, which made it possible for the first time to “march” an excavator over railway lines, rivers and roads, was outstanding in the period that followed. EGB was the first innovative and pioneering company to design and build a 30 kV slip ring.

In 1992, Peter Papla, the long-serving plant director, took over the successfully privatised company as part of a management buy-out and gave it back its historical name Elektrotechnische Geräte Böhlitz-Ehrenberg GmbH.

With the constant further development of the products and the high quality of the specialised machines becoming known, the company succeeded in acquiring many new customers and establishing the EGB brand throughout Germany.

In March 2023, Markus Radmacher took over the company as part of a succession plan.

He and his team are sticking to the company principles of excellence, innovation and consistency in order to continue developing and manufacturing sustainable products that drive the energy transition.

The company continues to focus on the development, manufacture, sales and service of: Cable reels for all reeling cables and hoses Slip ring assemblies and media transmitters (data, optical signals, liquid media) Low-voltage switchgear (lever, spindle and geared limit switches as well as snap-action and push-button switches in various designs) Terminal and distribution boxes for medium and high voltage.

OUR USPs

ELECTRIC REPLACES DIESEL

CUSTOMISED SOLUTIONS

SPECIALS

REMARKABLE FACTS AND FIGURES

Largest assembly hall with approx. 200 square metres

Approx. 1000 square metres of production space and 500 square metres of storage space

Approx. 700 square metres of office space

DIN EN ISO 9001 CERTIFICATION

AS-CERTIFICATION SSC*

PRIVATISATION

CHANGE IN OWNERSHIP

Our promise:

“Quality for generations!

As a family-run company, we stand for robust and durable products that meet the needs of our customers.”